Asme sec viii div i. Noise control problems exist where high pressure high temperature gasses are vented to the atmosphere.

Start Up Vent Silencer P R Acoustical And Engineering Works P Ltd

Steam boiler relief valves superheater header relief valves boiler startup and purge high-pressure.

. The specification of the proper steam silencer for a given application is based a number of factors. Selection of the appropriate silencer sizing relative to the steam flow. G The transmission loss is confined over a relatively.

After a suitably sized device has been selected it is installed at the pipeline purge outlets where fluid. Combination Vent Silencers Versatile Silencers HV Series vent silencers effectively silence high-velocity air steam and gas vents and blowdowns to atmosphere where sonic or critical conditions exist in the valve. The silencer reduces significantly the noise produced by steam discharges where it is needed to relieve.

The Vent Silencer Working Principles. Steam silencer noise reduction pressure relief ABSTRACT This project describes how power plants can make their own steam silencers. G Resonators used as side branches attenuate sound in the main duct or pipe.

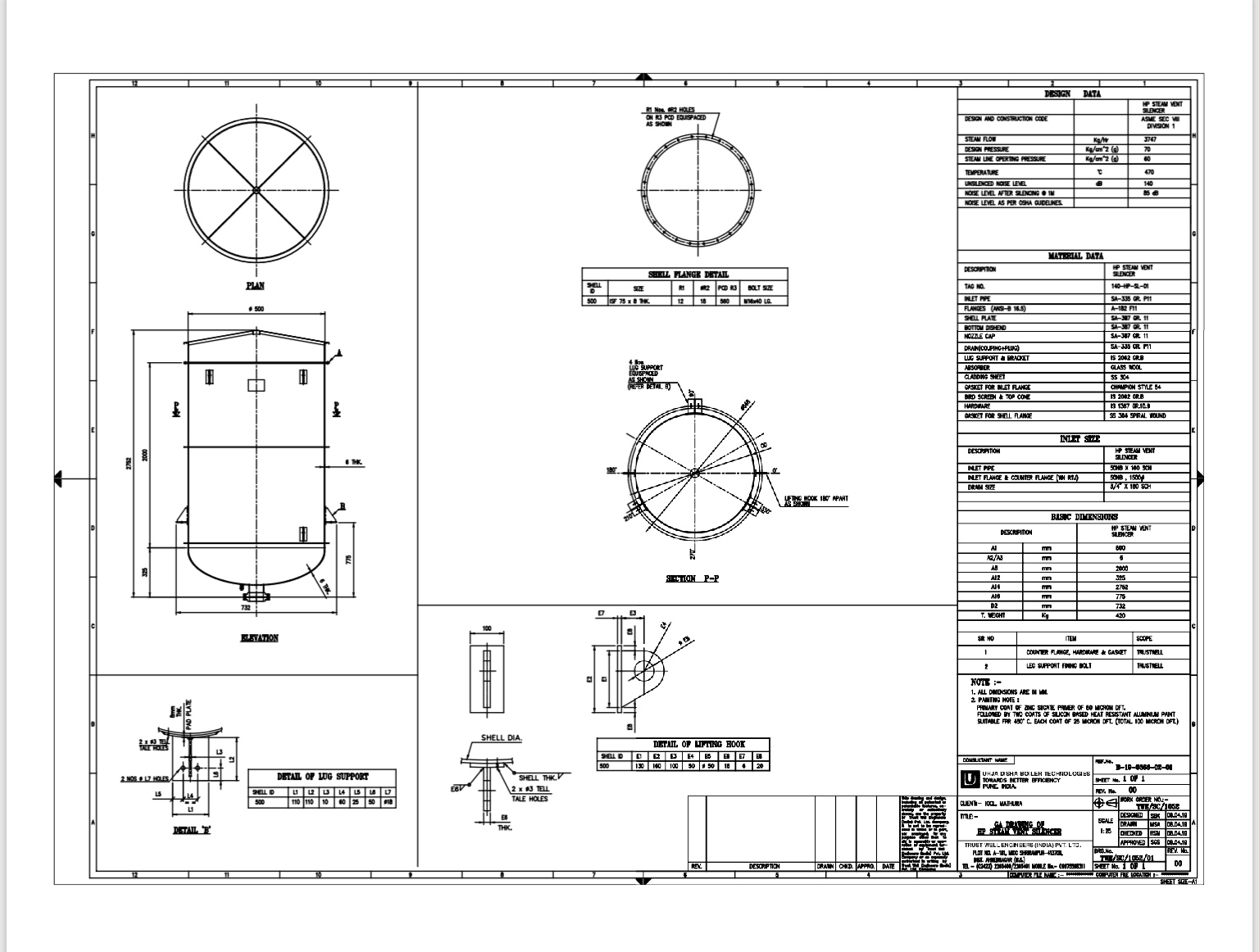

This study aims at running the CFD simulation for the steam vent silencer for different number of holes and diameter and hence finding an optimized design for the inlet diffuser for the flow to. Silencer backpressure a - allowed. Max blowdown mass flow rate lbhr temperature upstream of valve.

The silencer is for dry steam based on orifice plates. Dürr Universals vent silencers effectively silence high-velocity air steam and gas vents as well as blowdowns to atmospheres in which sonic or critical flow conditions exist in the valve. PULSCO Vent Silencers reduce the noise generated by the expansion of gas or steam from elevated pressures to atmospheric pressure.

Design of Mufflers and Silencers Noise and Vibration Short Course Dept. Innovation never stops ASFC keeps on developing the silencers so you can enjoy the quietness. The vent silencer data sheet shown in Figure 1 is a compilation of those forms.

Steam Vent Silencer Design Do-it -yourself Can anyone advise where I can find basic or detaileddesign guide for steam vent silencers. Stopson Italianas Steam Vent Silencers. The word silencer is instead referred.

Pwl at vent outlet without silencer lb in 2000. This noise is produced by the rapid turbulence of the mixing gas jet and energy release of the compressed gas. Vent and blow down noise is a function of upstream pressure and temperature type of gas being vented the valve size and type plus the effect of down stream piping.

For both of them the design is similar since we refer to vent silencers when being used to vent at a constant flow rate for a period of time. Engineering 21 University of Kentucky G The side-branch resonator is analogous to the tuned dynamic absorber. Single cycle silencers Optimised splitter design Steam silencers Vent silencers Start-up silencers Blow-off silencers Flash tank silencers Acoustic enclosures and claddings Facades and shrouds Partial HRSG enclosures Steam and gas turbine enclosures Supply and erection Flue-gas silencers HRSG outlet duct silencers Main stack silencers Id and Fd.

These absorptive silencers are used to suppress noise generated by high velocity gas streams such as steam vents safety relief valve outlets system blow down and purge outlets. The pressure at the inlet diffuser Silencer performance of the IMS design of vent silencer is never more than 05 barg to ensure exemption from the requirements of the Pressure Equipment Directive. Giving us accurate noise calculations and optimal compact designs.

More About Vent Silencers A vent silencer is a device that is intended to reduce the noise levels created when high-pressure gas or steam is expanded to the atmosphere. The two can be connected by a transition section. An example is used to illustrate an approach to the design of an acoustically treated expansion chamber for a typical noise problem caused by superheated steam vented to the atmosphere.

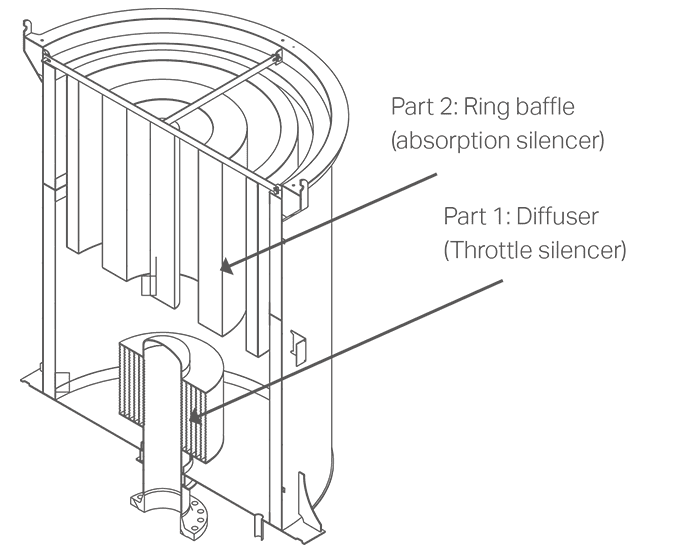

Asme b311 pipe code. Industrial steam vent silencers reduce noise via two primary principles to cover a wider sound frequency range. Vent silencer design is an experts job.

The data sheet is color coded to identify purchaser-supplied in-formation general important and necessary and vendor-supplied. The terms vent silencer and blowdown silencer refer to the relative application for which each one is used. One is set 22 bar 7050kgh other 12 bar 23350kgh.

If you need a tailored solution our steam vent silencers shop will engineer and manufacture industrial grade noise control waste recovery and emission control equipment with any combination of components. Vents use reactive components to reflect sounds toward the source rather than pushing the sound outward. Steam Vent Silencers are a combination of absorptive and reactive type silencers used to reduce the noise produced by the expansion of steam or gas from the elevated pressure level to the atmospheric pressure level.

Each Steam Vent Silencer is designed to attenuate the high as well as low frequency noise level to the optimum sound level. Efficient steam silencer design will reduce the noise level in industries that vent steam and other high-temperature fluids. Problem is I need to deal quickly angry local residents with two steam relief vents which currently discharge to a common 8 uncoupled vent pipe.

DB Noise Reduction steam silencers control sound through a reactive-absorptive process which provides good attenuation across all octave frequency bands. Efficient steam silencer design will reduce the noise level in industries that vent steam and other high-temperature fluids. The inlet of our silencers together with the noise generated by your valve is calculated using CONVAL-9.

An analysis is developed to aid in the design of the acoustically. At grade with silencer inlet at. Its simple design makes it economically viable.

Vent silencers find wide applications in high pressure vents steam vents safety relief valve outlets system blow downs and purge outlets etc. This sometimes necessitates an inlet diffuser diameter greater than the vent line. Maxim Silencers specializes in steam vent silencers.

As such it must be carried out by experiencedcompetent professionals. Typical pressure relief applications include HRSG units steam boiler super-heat headers boiler startup and high-pressure purge air vents natural gas. Vent Silencer Data Sheet Many engineering concerns consultants manufacturers and evaluation of vent silencers over the years.

As the noise travels its magnitude dissipates and dampens. The pressure at the inlet diffuser Silencer performance of the IMS design of vent silencer is never more than 05 barg to ensure exemption from the requirements of the Pressure Equipment Directive. The AFBR silencer can be mounted on any vent is easily installed and durable.

Blow Off Silencer And Vent Silencer For Industial Plants

Bachmann Industries India Limited Vent Steam Silencers

Steam Silencers Trust Well Engineers India Pvt Ltd Leading Manufacturer Of Waste Heat Recovery Boilers Steam Coil Air Pre Heater Economizer Soot Blowers Steam Silencers Heat Pipe Recovery System In Pune

Vent Silencers Controlling Noise Creating Within A Pipeline From Gas Or Steamflow

Schematic Of A Pulsco Vent Silencer Download Scientific Diagram

Cross Section Of The Designed Double Muffler For Steam Vents Noise Download Scientific Diagram

0 comments

Post a Comment